- Homepage

- Brand

- Length

- Material

- Alloy (45)

- Alloy Steel (24)

- Aluminium (7)

- Aluminum (4)

- Brass (12)

- Bronze (6)

- Carbon Steel (4)

- Cast Iron (14)

- Copper (9)

- Corten Steel (3)

- High Carbon Steel (3)

- High Speed Steel (12)

- Iron (4)

- Metal (135)

- Solide Carbide (14)

- Stainless Steel (12)

- Steel (44)

- Steel - Mild (6)

- Tungsten Steel (5)

- Wood (4)

- Other (2626)

- Model

- 001 (3)

- Cut50 (5)

- Digital Elite (5)

- Draper Lathe-300 (10)

- Infinity (4)

- Kry-pctr (4)

- Machine Tools (3)

- Metalworking Tools (3)

- Panoramaxx (2)

- Sealey Sm27 (12)

- Sim50rx (3)

- Ss-16 (20)

- Unspecified (45)

- Wes51 (2)

- Z20002m (3)

- 6040 (4)

- 1677026641 (5)

- 6323436443 (5)

- 7357556997 (8)

- 9278352914 (4)

- Other (2843)

- Unit Type

- Width

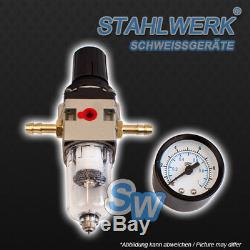

PLASMA CUTTER CUT 50 S HF INVERTER / WELDING MACHINE/ Cutting power up to 12mm

Contact with STAHLWERK Welding Machines. TIG AC/DC Welders with Pulse & Plasma Cutting.

ARC-Stick, Alu welding, Plasma cutting up to 12 mm. TIG AC/DC Welders with Pulse. TIG DC Welders with Pulse & Plasma Cutting. MMA ARC-Stick, Plasma cutting up to 12 mm. TIG DC Welders with Plasma Cutting.

MMA ARC-Stick, Plasma cutting up to 14 mm. TIG DC Welders with Pulse. Cutting up to 12-40 mm. DC MIG, MAG, TIG, MMA ARC-Stick. Over 100000 satisfied customers in Germany, Europe and Switzerland.

Test welding & plasma cutting: convince yourself of our high quality! Compact, lightweight construction with the greatest possible mobility. Cutting power up to 12 mm.Accurate and very stable arc. Powerful cutting speed which ensures high productivity. Plasma Cutter STAHLWERK CUT 50 S. A professional cutter for everyday use!

Conviction through excellent cutting quality! With the integrated Plasma cutter CUT 50 S can be cut without problems all conductive metals.

For example: aluminum, steel, copper, brass, titanium and so on (depending on material). CUT contact - Absolutely easy-to-use HF high-frequency contact ignition.. A light stroke over the workpiece is sufficient. Gas post-flow protects the tungsten electrode from excessive wear and protects the weld seam for oxidation. Gas/air post-flow time adjustable with 2 switching steps: 2.5 S and 5.0.Smart Cooling Fast cooling fan allows maximum power consumption and increases the operating time (ED) of the unit. Overheat protection starts as soon as the unit is overloaded. A yellow indicator light turns on and goes out as soon as the unit has cooled down again. Cutting power up to 12 mm material thickness (depending on material). With all our devices, we trust in MOSFET technology from Toshiba , whose innovative solutions set new standards in welding technology.

S-Guard-Housing is ergonomic, robust and operationally reliable: - Sturdy sheet steel housing, - Shock-proof, - Hard plastic formwork, - Control panel conveniently accessible and easier to operate, - Intelligent fan guide. The single-phase alternating current is to be protected in the household with a 16 A fuse. The welding machine is connected directly to the single-phase alternating current (AC) 230 V (+ -15%), 50/60 Hz operation. Excellent quality due to fully digital inverter technology The welding machine Profi-Plasmaschneider CUT 50 S has the most advanced inverter technology MOSFET (Toshiba).

The resultant special features such as high speed and precision of the control give the devices their excellent quality in welding and cutting. The Plasma cutter CUT 50 S is characterized by the following features. Power Plasma cutter adjustable between 10 50 A. Construction steel ST37 up to 12 mm.

V2a up to 10 mm. Aluminum up to 7-8 mm. Gas post flow Automatically controlled air afterflow time for the cooling system.

Overheat protectio Overheat protection goes on when the unit is overloaded. Safety degree of protection by enclosure IP21: - Protection against foreign material. Protected against solid foreign material with a diameter of 12,5 mm or mor. Protection against touch: Protected against access with a finger.Protection against water: Protection against dripping water. Pilot arc - non contact. Precise and very stable arc. High duty cycle of 60% at 50 A.

Intelligent housing design with optimized airflow. Clean cuts which do not require post-processing. Powerful cutting speed, ensuring high productivity. Maximum energy density with minimized heat distortion.No material distortion due to heat metal waste is minimized. A plasma beam that cuts any electrically conductive meal effortlessly. Due to the low deformation, thin sheets can be welded together again immediately. Low operating costs due to the use of air plasma instead of expensive gases compressed air is used. The long-lasting design and the demanding welding properties of the machines ensure a reliable daily use for the production welding work.

S-Guard housing robust and reliable. Hard plastic casing protects against damage. High ED (duty cycle) by intelligent fan control. The control panel is clear and ergonomic at the front. All settings are comfortable, accessible and easier to operate.Comfortable setting of the welding parameters via function selection and control dial. Inverter welding machine The welding inverter is an electronic welding current source. Inverter welding machines are built for all arc welding processes such as electrode, MIG/MAG, plasma and TIG welding.

Depending on the power, the devices are connected one or three phases to the electric circuit. Output current Plasma / CUT. 60% at 50 A / 100% at 30 A. Degree of protection by enclosure. 230 V AC (+-15%) / 1 (single phase). Dimensions Length x Width x Height (mm). 380 x 165 x 320. Technical requirements Plasma / CUT Compressor. An air compressor with at least 6.5 bar is required for cutting. A commercial building market compressor is also sufficient. Please pay attention to the performance. Make sure that the ground terminal and the workpiece have a good electrical contact; This applies in particular to painted or oxidized metal sheets and to metal sheets with an insulating coating.Do not attach the ground clamp to the workpiece that is to be separated. Maintenance of the cutting current source. Caution : To ensure proper functioning of the appliance, the appliance must be cleaned at regular intervals with the compressed air from the accumulated metal dust. The Mettal dust can cause short circuits, which could lead to the guarantee being voided.

The machine STAHLWERK CUT 50 S. Plasma hose "AG-60" 4,50 meter. Plasma accessories set 3-part (installed them each one piece already in the hose package). 1 nozzle (already at the plasma torch).

1 electrode (already at the plasma torch). 1 ceramic cap (already at the plasma torch). This is free for you. We want to avoid transport damage. Although both packages leave our house at the same time, in some cases, the machine comes first and the accessories are delivered one day later.

This is not the rule, but it happens. In our Shop you will find everything about welding and cutting equipment includes stick welders, TIG welders, MIG welders, multi-process welders, plasma cutters, also welding accessories and welding protective clothing. The Company STAHLWERK Schweißgeräte Deutschland e. We are your professional and reliable welding specialist. In STAHLWERK welding machines you have the latest inverter technology.

Highest quality standards in a premium brand and low prices to a product-performance-ratio. With which process you also weld or cut AC, DC, MIG MAG, MMA or CUT the STAHLWERK products range leaves nothing to be desired.In particular, it relates to the circuit board and the inverter. It does not extend to the housing and its external components and connecting parts, such as the hose pack or the mass clamp. It also does not extend to the supplied accessory, which is not used in the device interior. In order to ensure optimum support for our customers, our very motivated employees are always available to answer any questions.

Our employees are constantly trained and updated to the latest state of technical developments. This is a service that you can also personally convince yourself of here at any time. Visit us - We would like to invite you to a test welding in our company at Bonn. Convince yourself of our service! Sample welding on site possible.

The item "PLASMA CUTTER CUT 50 S HF INVERTER / WELDING MACHINE/ Cutting power up to 12mm" is in sale since Friday, April 24, 2015. This item is in the category "Business & Industrie\Metallbearbeitung & Schlosser.\Schweißen & Löten\Schweißen\Schweißgeräte & -brenner\Plasmaschneider". The seller is "stahlwerk-schweissgeraete" and is located in Weilerswist.

This item can be shipped to all countries in Europe.

- Marke: STAHLWERK

- FACHHANDEL: PROBE SCHNEDEN

- MARKENQUALITÄT: 5 JAHRE GARANTIE

- GERÄTEART: PLASMASCHNEIDER

- Herstellernummer: ED-E1191

- GTIN: 4260294081918

- EAN: 4260294081918